Highlight News

World News

Latest News

Editor Picks

Features and Events

Empowering Families My Parents Teachers Initiative

Empowering Families through My Parents Teachers Program

Building Strong Foundations

In the journey of parenting, having a solid support system is crucial. Enter the My Parents Teachers Program, a beacon of guidance and support for families navigating the complexities of raising children. This innovative initiative focuses on building strong foundations by empowering parents with the tools and resources they need to foster a nurturing environment at home.

Nurturing Parent-Teacher Collaboration

At the heart of the My Parents Teachers Program lies the concept of collaboration. By bridging the gap between parents and teachers, the program creates a cohesive support network for

Dive into Mammoth Interactive’s Game Design Course

Unlocking the Potential of Mammoth Interactive Courses

Embarking on a journey of learning is often likened to traversing uncharted territory. With Mammoth Interactive courses, this journey becomes an exhilarating expedition into the realms of technology, design, and creativity. Let’s delve into the transformative power of these courses and how they can empower individuals to master new skills and unlock their full potential.

Mastering the Fundamentals: Building a Strong Foundation

Every skyscraper needs a solid foundation, and so does your journey into the world of technology. Mammoth Interactive offers courses that serve as the bedrock for your learning experience. From web

Igniting Minds Coding Education Revolution in Schools

The Evolution of Coding Education in Schools

Introduction

In recent years, coding education in schools has undergone a significant transformation. From a niche subject to an essential part of the curriculum, coding is shaping the future of education. Let’s explore how this evolution is reshaping the learning landscape.

The Rise of Digital Literacy

In today’s digital age, proficiency in coding is akin to literacy in the 21st century. Schools recognize this shift and are integrating coding into their curriculum to equip students with essential digital skills. As a result, students are not only consumers but creators of technology.

Early Exposure

HSE Parenting Course Nurturing Stronger Family Bonds

Nurturing Stronger Family Bonds with HSE Parenting Course

Understanding the HSE Parenting Course

The HSE Parenting Course is a comprehensive program designed to equip parents with the knowledge, skills, and resources needed to navigate the challenges of raising children in today’s world. From managing behavior and fostering positive relationships to promoting emotional well-being and supporting development, this course covers a wide range of topics essential for effective parenting.

Empowering Parents with Knowledge

One of the key objectives of the HSE Parenting Course is to empower parents with knowledge about child development, communication strategies, and effective discipline techniques. By understanding the

Exciting Math and STEM Activities for Preschoolers

Exploring the Fascinating World of Math and STEM Activities for Preschoolers

Introduction: Unlocking the Wonders of Early Learning

Preschool years are a time of immense curiosity and exploration, where young minds are eager to absorb knowledge like sponges. It’s during this crucial developmental stage that introducing children to the wonders of math and STEM (Science, Technology, Engineering, and Mathematics) can lay a solid foundation for their future learning journey. In this article, we delve into the importance of incorporating math and STEM activities into preschool education and explore some engaging ways to ignite young learners’ curiosity.

Why Math and STEM

Supporting Pregnant Teens Creating a Safe Home Environment

Supporting Pregnant Teens: Creating a Safe Home Environment

Understanding the Importance of Home for Pregnant Teens

For pregnant teenagers, the home environment plays a crucial role in their well-being and the well-being of their unborn child. Creating a safe and supportive home environment is essential to ensure that pregnant teens feel nurtured, empowered, and prepared for the journey ahead.

Providing Emotional Support

Emotional support is paramount for pregnant teens, and the home should be a place where they feel understood, valued, and supported. Family members, caregivers, and friends can offer encouragement, empathy, and a listening ear to help alleviate stress

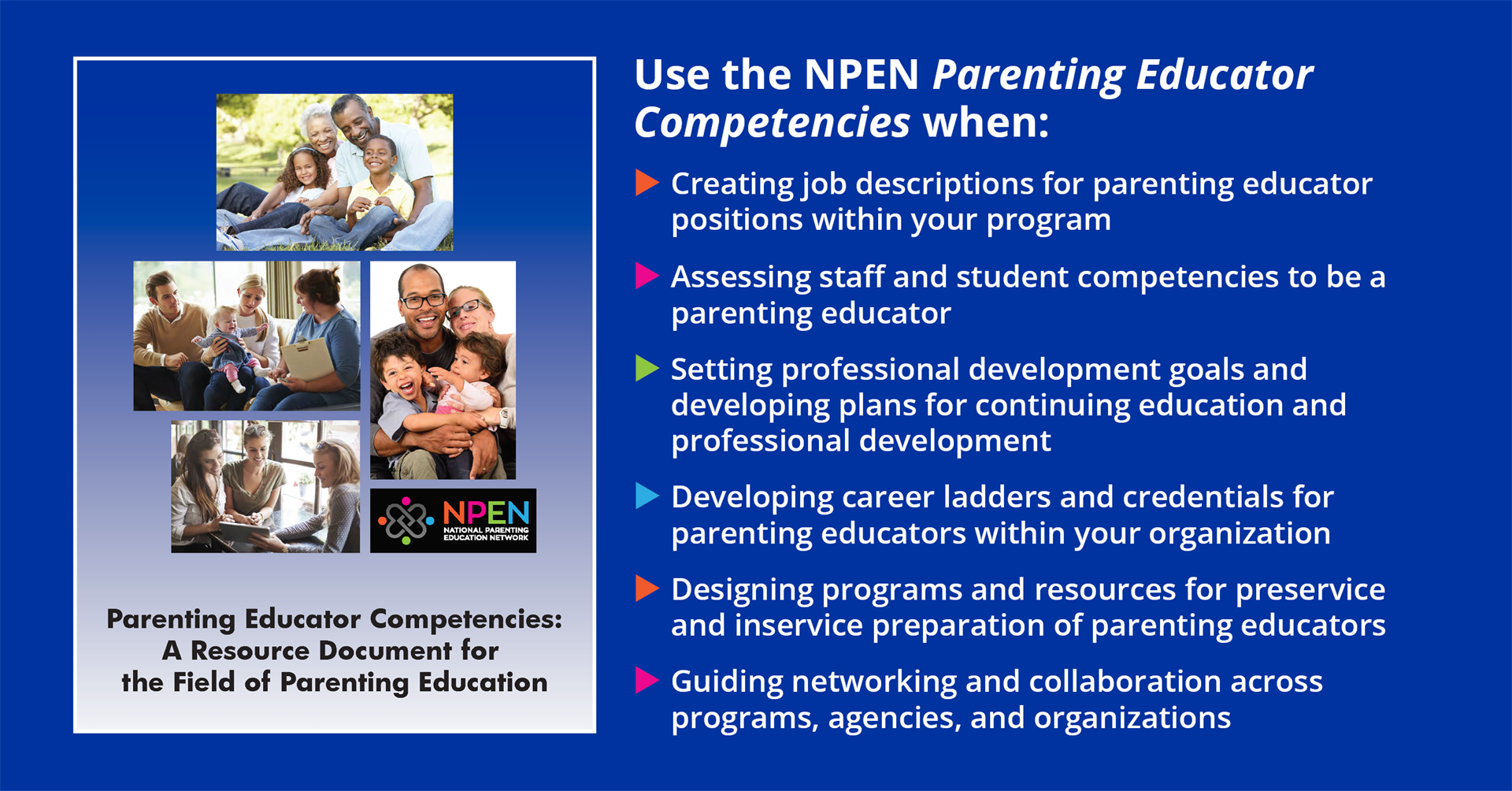

Nurturing Growth The Role of Educator-Parental Collaboration

Navigating the Role of Educator-Parental Dynamics

In the intricate web of education, the relationship between educators and parents plays a pivotal role. Let’s delve into this dynamic alliance and its profound impact on a child’s learning journey.

The Fusion of Roles: Balancing Act or Juggling Act?

Educators often find themselves straddling the line between professional responsibility and a more nurturing, parental role. This fusion of roles can be both enriching and challenging, requiring a delicate balance to meet the diverse needs of students.

Communication: The Backbone of Collaboration

Effective communication serves as the cornerstone of successful educator-parent partnerships. Transparent dialogue

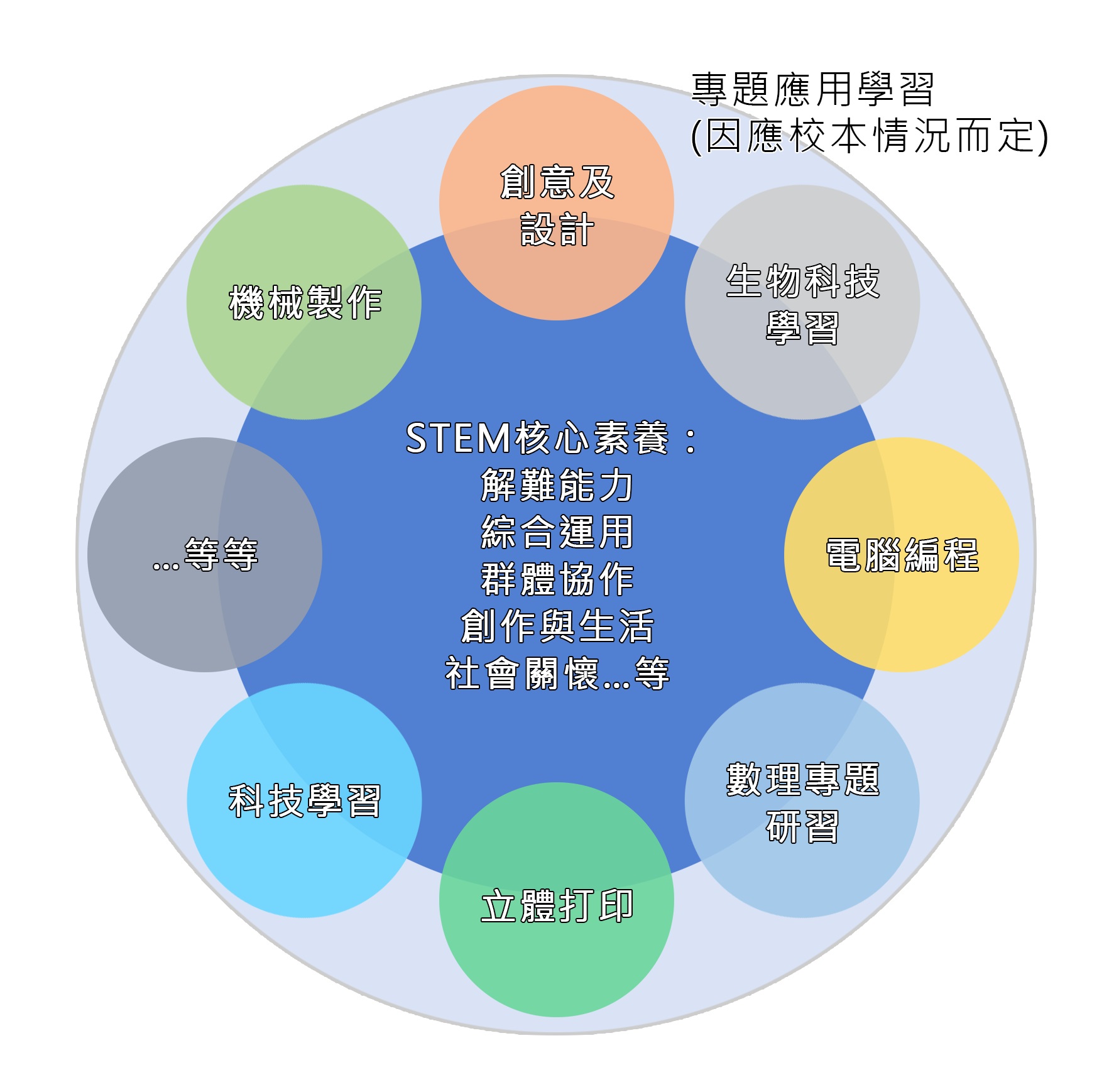

Fostering Innovation Global STEM Education Initiatives

Fostering Innovation: Global STEM Education Initiatives

Empowering Tomorrow’s Leaders

In the dynamic landscape of global education, STEM (Science, Technology, Engineering, and Mathematics) initiatives have emerged as catalysts for change, empowering tomorrow’s leaders with the skills and knowledge they need to thrive in an increasingly complex world. From grassroots community programs to multinational partnerships, global STEM education initiatives are shaping the next generation of innovators, problem solvers, and changemakers.

Driving Progress Through Collaboration

At the heart of global STEM education initiatives lies a spirit of collaboration and cooperation. Across borders and boundaries, educators, policymakers, industry leaders, and community stakeholders come together

Master Coding Professional Development for Teachers

Empower Educators with Coding Courses

Bridging the Digital Divide

In today’s rapidly evolving technological landscape, the role of educators has expanded beyond traditional teaching methods. With the increasing importance of digital literacy, coding courses for teachers serve as a bridge, empowering educators to effectively navigate and incorporate technology into their classrooms.

Elevating Teaching Practices

Coding courses for teachers are not just about learning to code; they’re about elevating teaching practices to meet the demands of the 21st-century classroom. By integrating coding into their curriculum, educators can enhance student engagement, foster critical thinking skills, and prepare students for future success in

Unveiling STEM Introducing Exciting Learning to Students

Unveiling STEM: Introducing Exciting Learning to Students

Understanding the Essence of STEM

Introducing STEM to students marks a significant shift in educational approaches. STEM encompasses Science, Technology, Engineering, and Mathematics, offering a holistic learning experience that prepares students for the challenges of the modern world. This integration of disciplines fosters critical thinking, problem-solving skills, and innovation from an early age.

Inspiring Curiosity and Exploration

One of the primary goals of introducing STEM to students is to spark curiosity and foster a sense of exploration. By engaging in hands-on activities, experiments, and projects, students develop a passion for learning and a